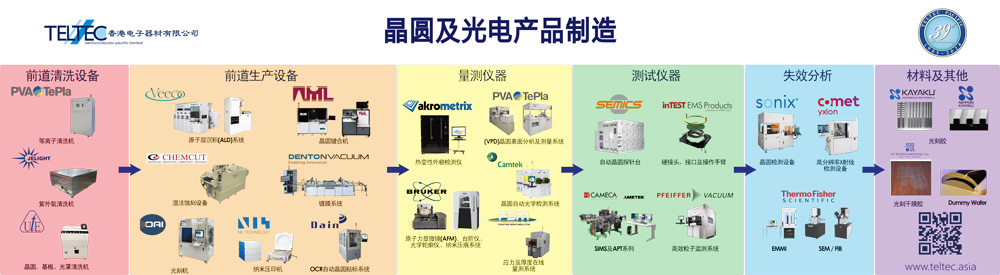

產品推薦

Munich Metrology VPD 系統及模組 產品WSMS - 晶圓表面測量系統Munich Metrology 提供了最先進的,完全整合的 VPD 測量系統。該 WSM..

$0.00

Kayaku Advanced Materials

SU - 8 2000 系列光刻膠

SU-8 2000 系列 - 永久性高深寬比負型光刻..

$0.00

X射線檢測設備

性能特點

- 平台化設計,實現產品客戶訂制化

- 使用開放式X射線管及平板數字探測器,領先業界的清晰像提供者

- 射線管的靶功率高達15瓦,幾何放大倍數達3..

$0.00

美國 Denton Vacuum金 / 碳鍍膜機

蒸發膜的厚度分佈

蒸發源的排放分佈特性可用於確定真空室中用於生產均勻厚度塗層的正確幾何形狀。

在..

$0.00

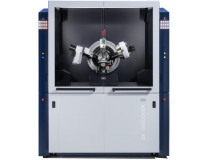

X 射線衍射 (XRD)

D8 DISCOVER 系列

D8 DISCOVER系列是市面上最准確、功能最強大和最靈活的X射線衍射解決方案。從典型的粉末衍射到尖端材料研究,覆蓋範圍極廣,它還..

$0.00

合作夥伴

.png)

.png)

.png)

-200x110.png)